Different types of sanding

Sanding has an integral part in woodcraft because it can smooth the surface of the wood. So, in this article, we are going to introduce different types of sanding and their use.

In order to sand, we need sandpaper created by a paper in which large stones and grains are glued. This tool is mostly used for shaving and smoothing the surface of works such as wood, plastic, iron, stone, and so on.

Sanding is available in different models like stone, paper, hand and electric sanding. Consequently, we can use it in various jobs.

Application of sanding

Regarding industry, we use sanding in construction, carpentry, factory and et cetra.

Paint the building.

According to building, laborers mostly employ sanding to paint the building. Furthermore, almost 80 to 320 pieces of sandpaper are often utilized in painting the building. The size and shape of the sandpaper in the building painting are similar to A4 paper. Some sanders are sold in meters called meter sanding which is produced from 40 to 100, and this is done 50% by hand and 50% by sanding machine.

Paint the car

A lot of sanding numbers from 120 to 2500 are used in painting the car because of the elegance and purity, sanding is done by hand.

Sanding the wood

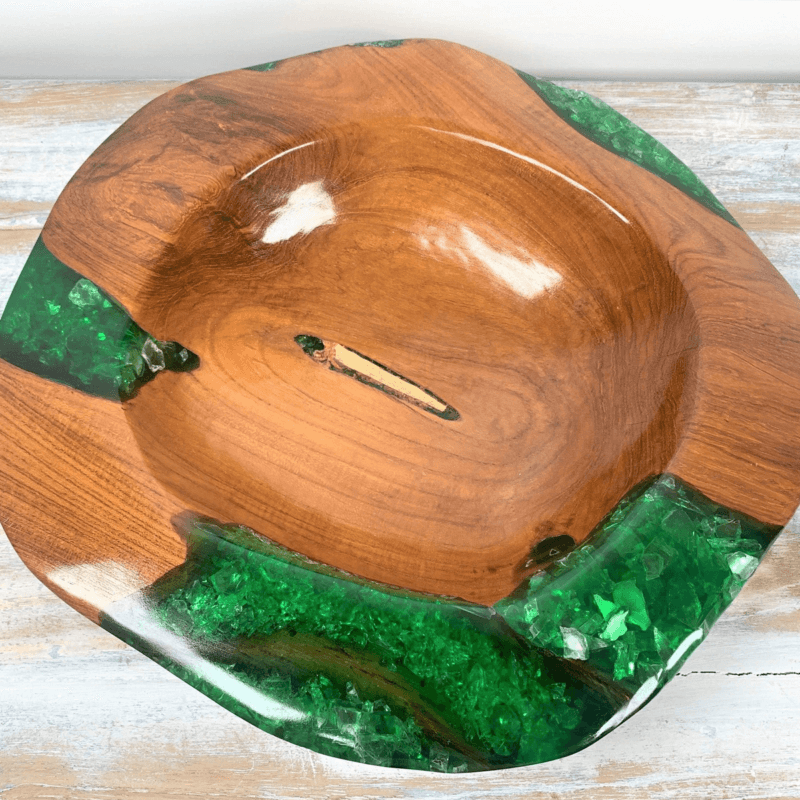

Thanks to sanding, we can make the surface and edge of wood smoother. Consequently, it can help us to produce some special handicrafts by means of them. For example, if we want to produce a table using a piece of wood and that wood was so untidy, then it is likely that the customers do not like such a table to put it in their house. Furthermore, sometimes the wood which is not sanded can scratch the fingers when you tough it. Consequently, producers make it smooth through the use of sanding paper.

Sanding the iron

Sanding iron is another significant use of sanding because it can assist us to make the surface of iron smoother. The edge of cut iron can be perilous because it is sharp and can easily cut hands. Therefore, we have to sand it using iron sand to make it so smooth.

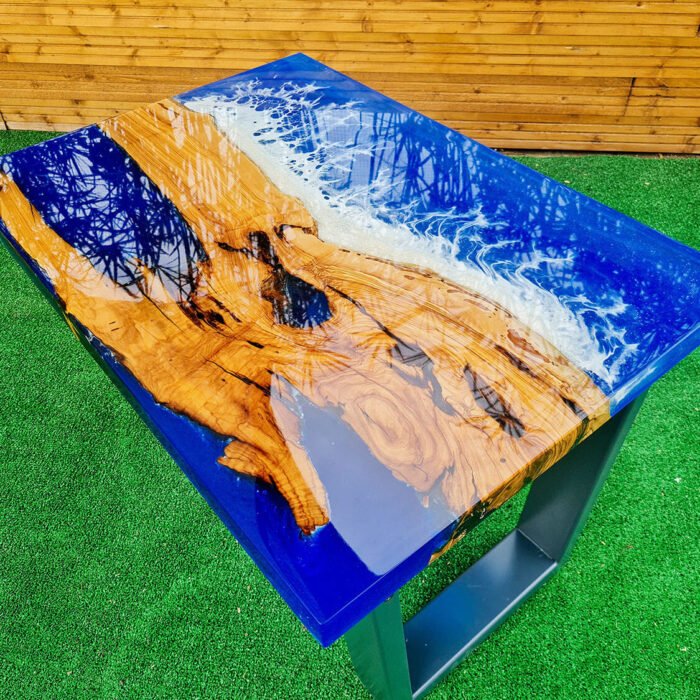

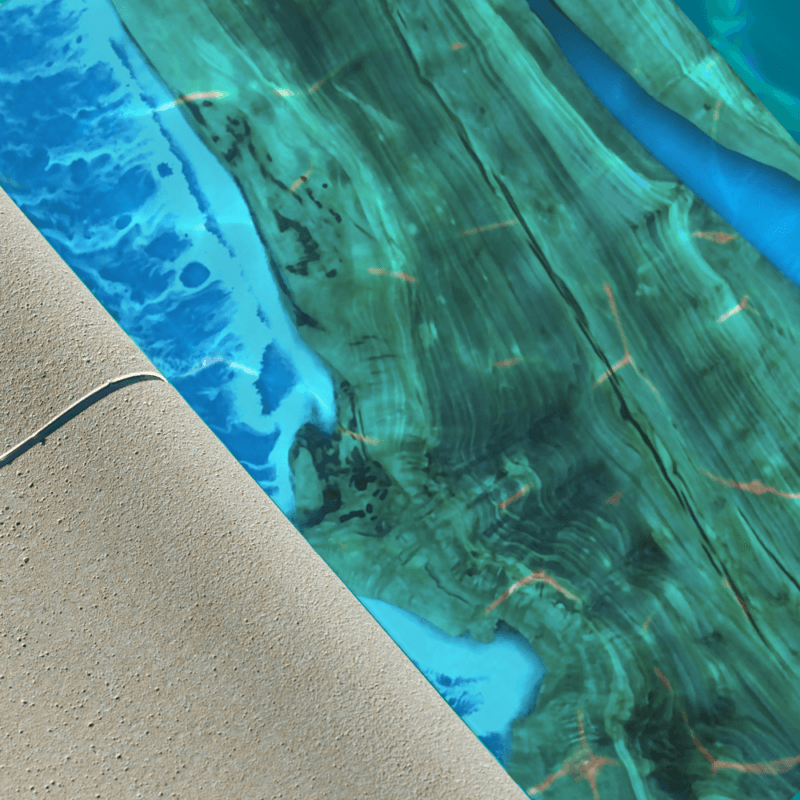

Sanding epoxy table

The most important role in creating epoxy tables is sanding as it can make the surface of a table more exquisite and transparent. Almas Turkey uses sanding at first after selecting a wood because we surface of the wood affects the resin and other material. Consequently, we try to make the surface of the wood smoother. It also can help us to clean the wood before the polishing phase. In order to clean the wood, we use 80 to 100 pieces of sandpaper, which is done with a sprayer. Spray sandpaper has a high speed and cleans the wood faster.

The process ends when we pour the resin before waiting until the resin dries completely. Then, we commence sanding the surface of the epoxy table to make it shinier and more transparent. In this stage, if the surface of our table possesses many waves, then it is likely that we should employ sandpaper 40 and 60 in order to smooth the surface of the table. However, if the surface of the table becomes smooth, we start from 120.

Sanding 40 to 320 is used to smooth the surface of the table, and you should note that the number of sandpapers rises with the smoothing of the table surface and the lines that the previous sanding fell on the table slowly continue to higher numbers. It is used from number 400 onwards to delete scratches and scratches on lower numbers and also to polish the surface of the table and continues until number 4000.

One thought on “Types of Sanding”