Drying Wood Using the Industrial Oven

Since we have talked about drying wood in the open air in the previous article, in this article we are going to explain Drying wood using the industrial oven and drying using the heater. Generally speaking, wood should be dried before use since if we use wet wood, it can cause some irreparable problems such as resizing, reshaping and so on. Consequently, drying wood is of vital significance.

How to work the industrial kiln

First of all, we have to know how the situation of a kiln soil should be. Firstly, the wall of the kiln ought to be covered using silk and stone completely so that it can keep the heat inside of itself. The fans are another significant piece of equipment that you should use inside of a kiln room. Fans help the air circulation.

Another significant tool that we have to install in this room is the sensors that can detect the temperature of the environment and humidity. This part is essential because if we do not know about the weather inside of the kiln, then it is likely that the process of wood drying exceeds the threshold and all the moisture of wood becomes evaporated. Therefore, the wood gets unusable.

Equipment

According to the equipment dries the moisture, this equipment is controlled using programs. For example, water sources which assist us to inject water into the wood. When the wood becomes so dried, we have to inject water into them so that we do not let wood crack.

Also, the torch is utilized to heat the wood. Sensors installed in the room control the heat of the torch and change the heat of that. The humidity puller is another tool that helps to remove the wet. The most important equipment is the control panel of the kiln because we can control all equipment using that. This section has a direct relation with sensors and fans, which means that it controls when the fans are turned on or off or when the water is injected or not.

Heating Room

This is a semi-industrial oven which has no more equipment than an industrial oven. This is a room with a covered wall and a heater and fans to dry the wood. Although it is a good method in comparison with drying in the open air, it still is not standard as high as the industrial kiln. Sometimes it dries more than the standard degree which hurt the wood.

Result

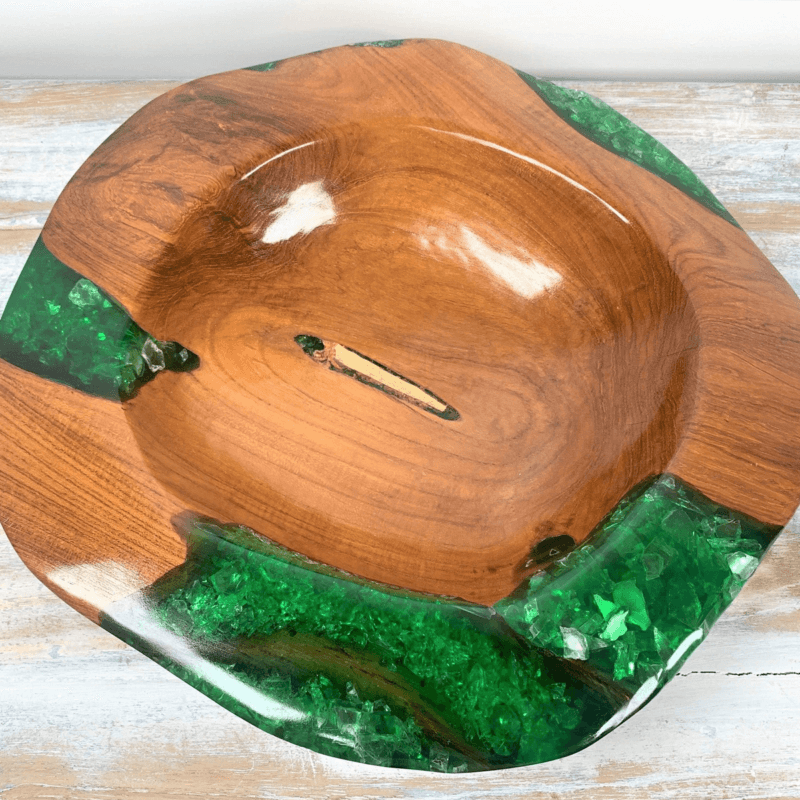

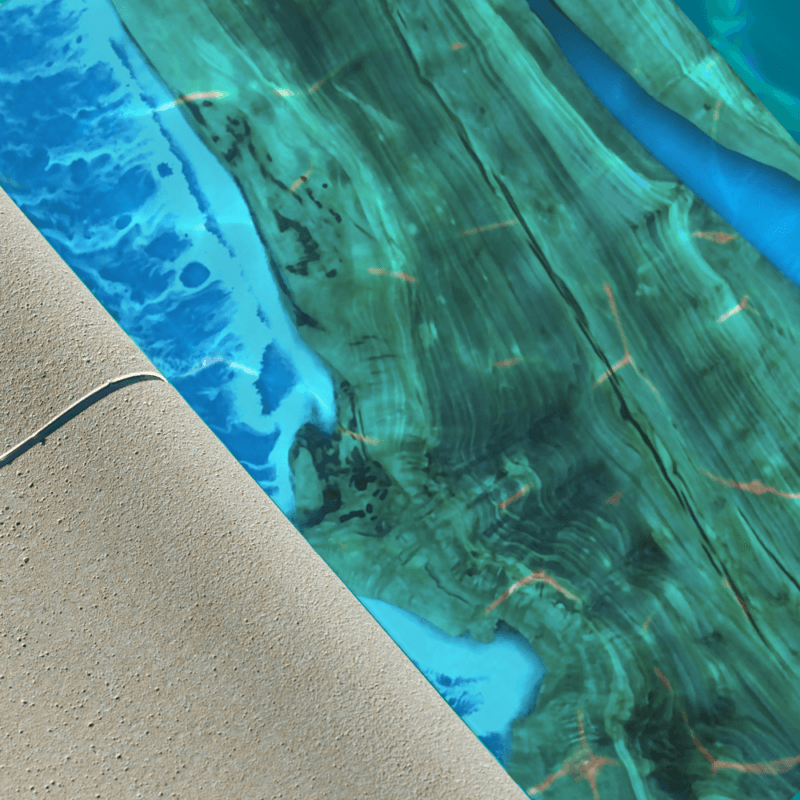

Drying wood using the industrial oven is one of the more common ways of drying wood that most factories and wood producers use it. It is the standard and safe way. If the wood become wet and we utilize it, it would hurt the woodcraft which we are going to create.

You can read more about resin and more such as epoxy clock, epoxy floor, epoxy accessories, epoxy panel, MDF, detecting wet wood and so on in Almas Turkey blog.

Source

https://www.nyle.com/kiln-drying-systems/lumber-kiln-drying/softwood-kilns/