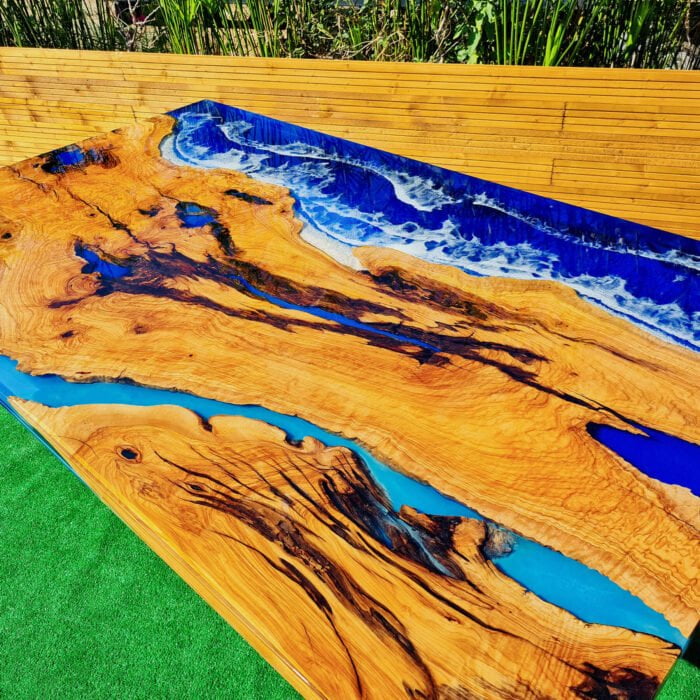

Epoxy Resin Mold

Epoxy Resin Mold which is one of the most crucial things to developing a resin table is the mold of that. In this article, we are going to talk about how epoxy resin mold is created.

If you have lately started to work in this field it would definitely be an insurmountable barrier for you if you do not have any information about the epoxy resin mold.

First of all, it is significant to know that resin becomes hard over the time, this means that the mold of that should be in the desired state to create resin objects and resin tables.

There are 2 kinds of templates that are used for various resin models:

- Silicone

- MDF

Silicone mold:

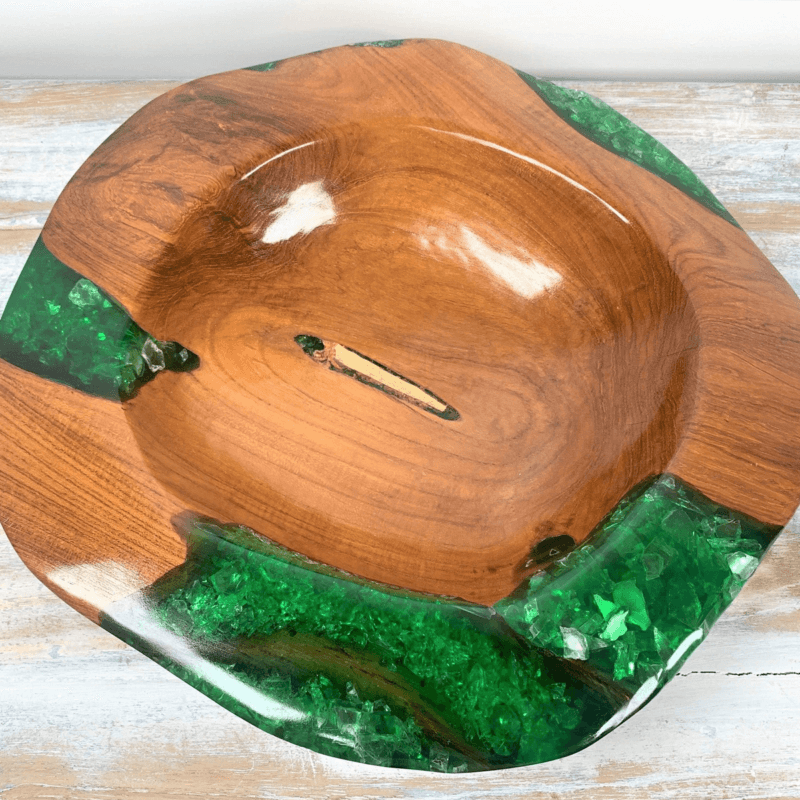

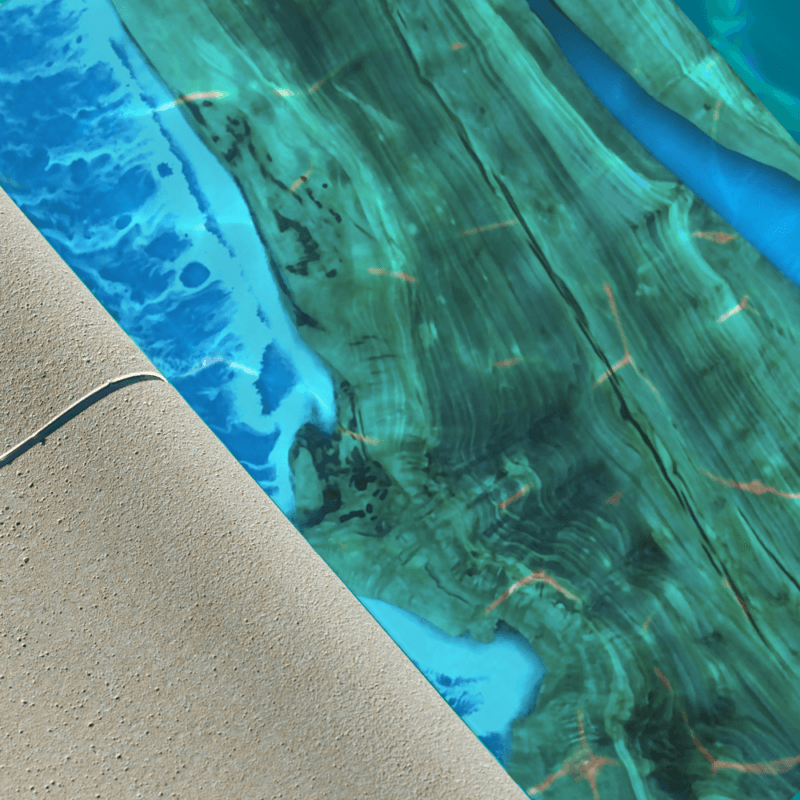

We employ silicone molds to develop 3D objects like decorative pendants due to their pliability. As you know our works are handcraft and woodcraft, this means that we can create any models that the customers order. For example, animal molds, fruits, and so on.

MDF mold:

This kind of mold is suitable for those who want to pour a considerable proportion of resin and make sure that the mold is strong. This kind of table is appropriate for them. It is also a mold with a flat floor.

Clamp for creating epoxy table

A Clamp is a piece of equipment utilized in MDF molds. However, other industries jobs use clamps during their jobs, and it is a practical tool.

Clamp application

We use a clamp in order to hold two objects along with holding the sides of the mold. In epoxy table firms, we utilize various forms and sizes of the clamp.

Clamp form

Generally, the clamp looks like the letter F with an immense stable horizontal bar and a tiny vertical bar at the top. Furthermore, the next vertical bar is attached to a lever that could be relocated and controlled. The lever is utilized to harden the mold or hold the mold.

Mold for making epoxy table

MDF or melamine sheets use to make the mold. The process begins with cutting the sheets to the size of the bottom of the mold. Then, we cut 10 cm in length and width for the four sides of the MDF.

What can we do to prevent the resin from sticking to the mold?

In order to have clean work in this stage, make sure the resin does not stick to the mold. If you want to forbid the resin from sticking to the mold, there are some methods. Firstly, you can spray the bottom of the mold and the walls of the mold, or you can cover the mold. Using clean glue is another method, which needs aquarium glue to paste the seam of the mold.

Then, we close the mold with a 4.5 cm screw that is particular for MDF. we utilize a cordless drill in order to perfume the work faster and wait 1 hour after closing the mold so that the glue dries entirely.

How to separate the table from the mold

One of the significant phases could certainly be separating the table from the mold which is a big difficulty for those who produce epoxy tables face.

you can easily remove it if we glue the mold and sides rightly using. When molding and gluing the mold and sides rightly, you can remove straightforwardly the mold with a few hammer blows.