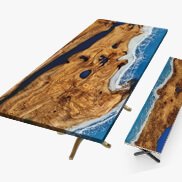

The Wood Selection Process to Make a Resin Table

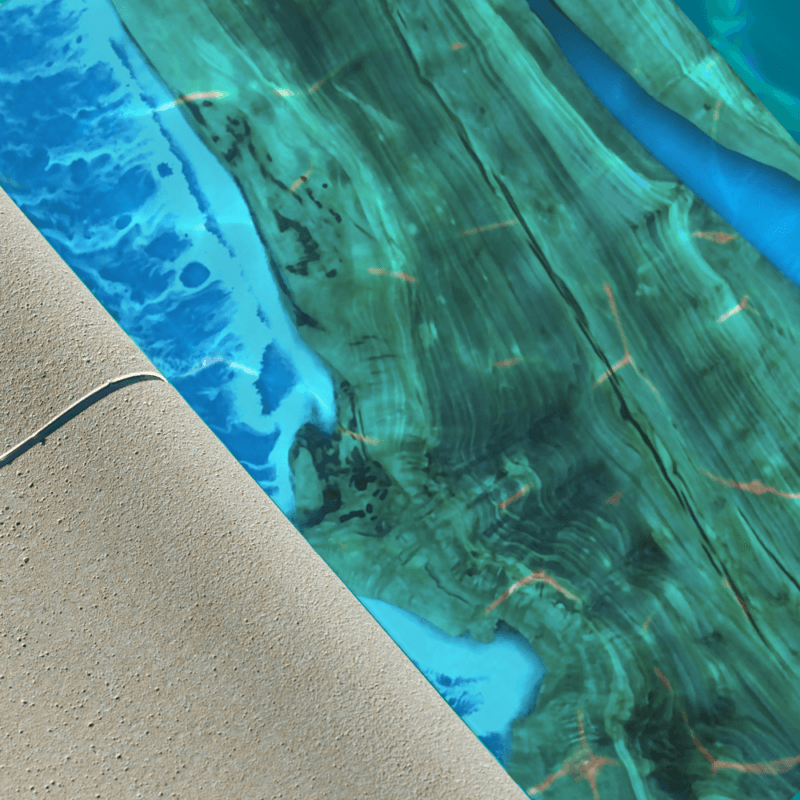

The wood selection process to make a resin table is one of the paramount matters in epoxy resin. Firstly, we strive to examine the material of wood so that we are sure about that before using the wood. Next, there are a bunch of activities that we have to do in order to have appropriate resin wood. Because when we are pouring resin and making a table, the wood should not have any problem. Thus. This level is seen as begin of great importance.

What type of wood is convenient to create a resin table?

There are disparate models including:

olive

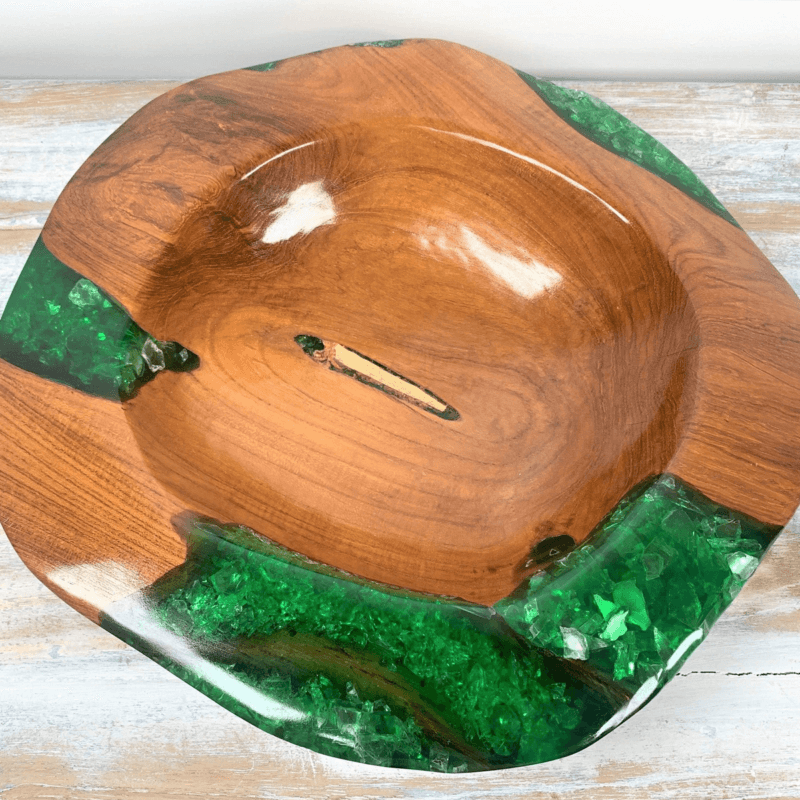

Walnut

Mappa Burl

Jujube

However, the world-renowned and popular model among woods is the olive tree because of its design.

Negligible significant points in selecting the wood

- Narrowness of wood

- CNC

- Wood moisture

- Wood size

- Molding

- Wood cutting machine

- Clean and non-greasy wood

Narrowness of wood

The narrowness of the wood relies on the view of the dear customer, but in enormous tables it must be 4.5. Furthermore, When the narrowness of the wood becomes less than the normal size, its stability would decline.

CNC machine

Peeling is requisite to conserve the wood surface pure and smooth. peeling has two methods:

- Performed by manpower.

- CNC machines perform the method perfectly and quickly.

Thanks to the computer, the CNC machine peels both manually and automatically.

Wood moisture

The wood misses its original form and color when it gets humid. Consequently, our wood would not definitely be salient wood.

Wood size

The size of the wood relies on the kind of wood. For instance, the olive tree does not grow because of the lengthy growth of the trunk.

Note

Some people strive to make artificial holes on the stub of the tree and fill some points of that. However, we believe that the fractures and holes of the woods have a unique beauty.

Molding

Molding depends on the size of the table ordered.

We require various equipment to develop the template

- MDF or melamine sheets

- Aquarium glue

- Spray or label

Molding steps

Firstly, glue the MDF sheets along with aquarium glue to secure the sides so that the resin does not come out of the mold. Next, we spray the bottom or corners of the mold. we label them so that the resin does not adhere to them.

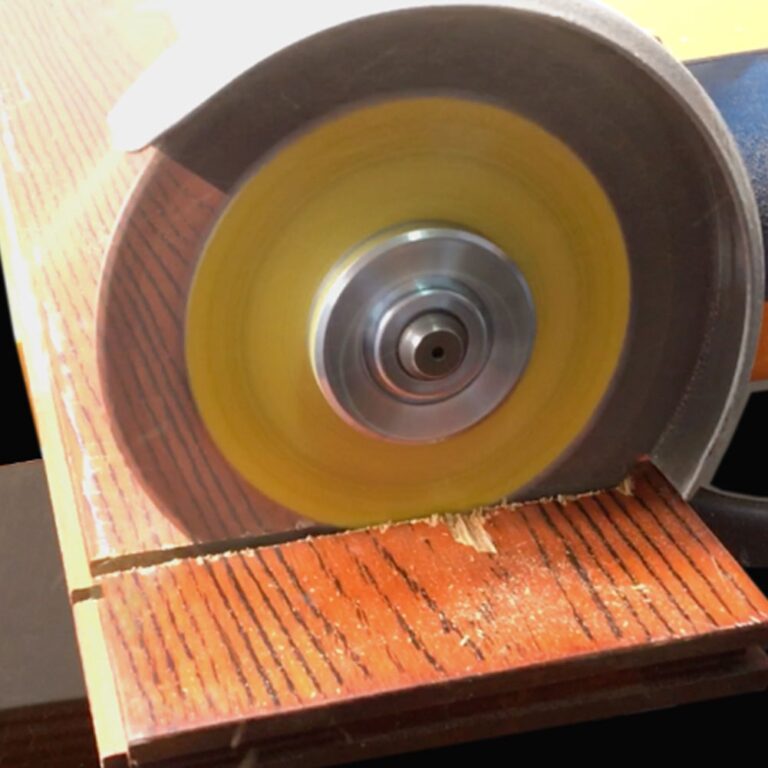

Wood cutting machine

There are two various kinds of wood cutting machines

- Rolling cutting machine: this is suitable for those woods that are so thick.

- Disc cutting machine (round cutting): This manual machine is suitable for those wood that are less thick

Clean and non-greasy wood

The surface of the woods is most important. So, we should be careful not to spill oil on the wood surface and maintain it clean. This is because of that If the surface of the wood is dirty, the table would definitely damage due to the resin we pour. This means that the resin will get the form of cloudy on the table. Consequently, watch out before it and clean the dirtiness

3 thoughts on “The Wood Selection Process to Make a Resin Table”