Applications of Epoxy Resin

There are some categories for applications of epoxy resin in the industry, but it is better to introduce the concept of epoxy resin firstly, then we are going to explain the applications of the resin.

Natural and synthetic are the main kinds of Resin, which are sticky and can be lawful in alcohol although water do not dissolve that . Furthermore, depending on chemical composition and consumption, we categorize resins according to both applications in industry and the field of art.

Natural resin

Natural resin is received through natural plants. One of the best trees for the resin is the pine tree sap. Also, the interesting thing is that the cute amber stone is utilized in designing cases because of the tightening of this plant resin. Pomegranate resin has been employed for many years, say, for sealing boats, food dishes, embalming corpses, etcetera.

Synthetic Resin

Thanks to technological advances, it is showed that resin can be changed into the polymer, which means that humans can discover synthetic resins after that. besides, synthetic resins are the main material of polymers since they are more straightforward to filter. “resin base” and “hardener” are two-element of the resins family compounded together in a certain ratio, according to its formulation and application so that they can be used in the desired surface or mold.

What is epoxy resin?

The main material of the work is resin base or component A, which needs tightener element B, the epoxy hardener. Resin base has various kinds, which is “Bisphenol A”. Types of widely used hardeners for epoxy

Moreover, the most extensively employed epoxy hardeners used are divided into two principal categories:

1) Polyamine Hardeners

Application of polyamine hardener

A particular Kind of hardener, polyamine, is often utilized in decoration because it is colorless and able to be put in volume. Furthermore, the polyamine hardener has two main characteristics. Firstly, it is narrow and the second is insoluble.

According to our discussion, these two elements must be compounded with each other in a certain share, regarding formulations of the factory. Then, it is poured into the desired container or mold so that it reaches the maximum tightness and catches the form of the mold after a modified period of time.

In order to manufacture resin tables, resin jewelry, abstract paintings and resin decorative parts, the above-mentioned hardener is utilized.

Why polyamide is not suitable for making jewelry and resin tables

Because of the considerable concentration polyamide has in comparison with the polyamine, it has to be joined to a solvent so that we could use it. This added solvent would definitely stay in the system and could make the resin become fragile in enormous contents.

Moreover, the dark color of polyamide can make it inappropriate in decorative works. Consequently, it is just utilized in epoxy flooring as a narrow layer for floor primer.

2) Polyamide Hardeners

Application of polyamide hardener

Polyamide is another hardener that could be compounded with epoxy resin. It is reddish orange in color and has a satisfactory density. Besides, polyamide is soluble which means that you could dilute it using adding main solvents to the polyamide hardener. However, This type of tightener is not appropriate in order to make resin tables, resin jewelry and resin decorative parts. On the other hand, it is certainly employed for epoxy flooring.

How does epoxy resin dry?

When it comes to its formulation, the epoxy resin dries totally after negligible hours in a day, and it also takes a week for the epoxy resin so that it is able to reach its topmost hardness and chemical bonds to shape between the resin and the hardener. Drying time and epoxy curing time rely on the kin of resin and hardener.

Applications of epoxy resin:

Nowadays, one of the widely used materials in disparate applications is epoxy resin utilized for around a half century. Not only does it use in the coating industry, but also it is able to use in other different industries like civil engineering, aerospace, automobile industry, wood industry, and so on.

Thanks to the chemical resistance Epoxy resin has, it can resist corrosion. Thus, although they are part of the costly synthetic resins, they are employed in industry and art.

This type of epoxy resin is entirely transparent which means that we can use it for many aims. like:

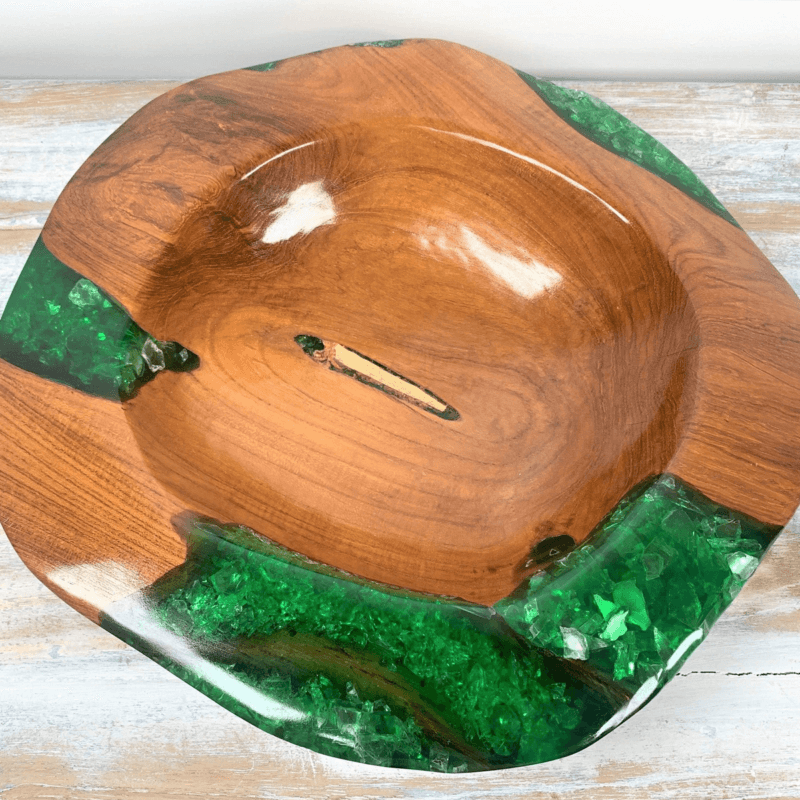

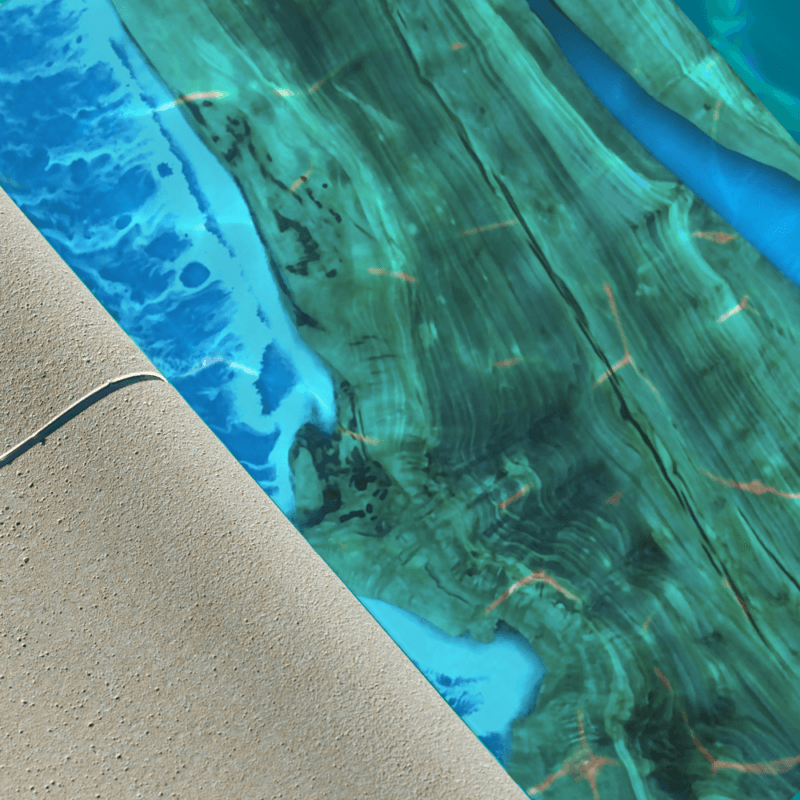

1)Epoxy Wood Resin

Epoxy Wood Resin

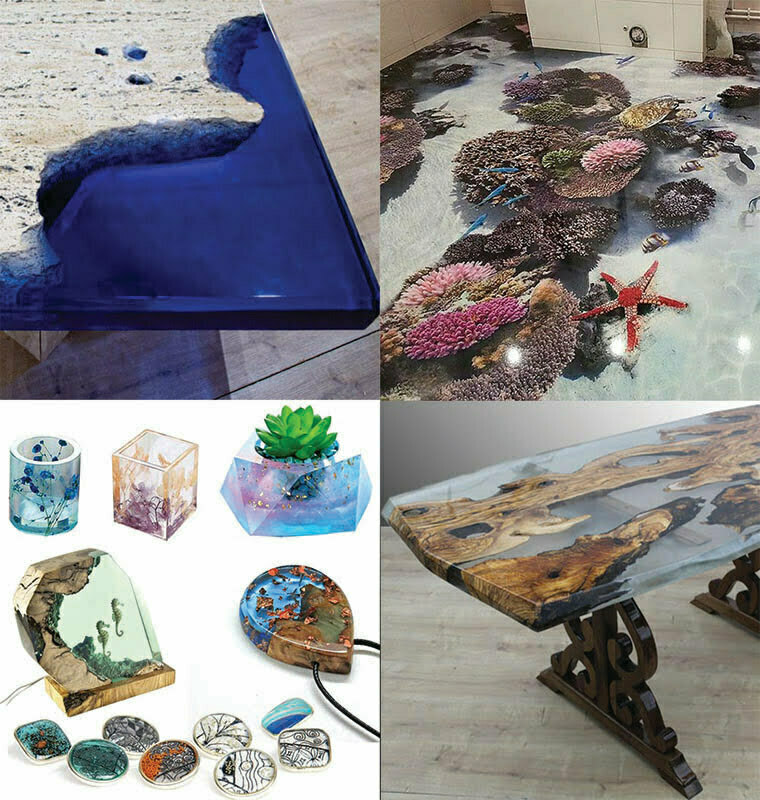

making tables and decorative stuff are the novel fields of working with epoxy resin, each of which is created using compounding epoxy resin and wood. It has the following applications:

- Persistence to wood and closing its pores;

- Creating various kinds of compound tables;

- Manufacturing decorative tiles;

- Making resin necklaces and bracelets with the assistance of wood epoxy resin;

- Polishing and displaying the beauty of wood with the help of epoxy resin;

Hence, This type of epoxy resin is utilized in the manufacture of decorative elements and has paramount profitability and income.

2)Decorative Wood Resin

Decorative Epoxy Resin

This type of epoxy resin is different in usage depending on the types of decorative epoxy resins:

- Epoxy rhinestone resin

- Epoxy jewelry resin

- Abstract panel epoxy resin

- Epoxy resin for bulk containers and catering

In addition, Epoxy resin is popular in the field of making resin rhinestones and decorative stones. It can be earned superficially due to the ease of work and the requisite versatile tools. Also, Fast performance, easy sales and acceptable efficiency are the main features of this type of work.

3)Epoxy Flooring Resin

Epoxy Flooring Resin

Flooring is one of the common working areas of using epoxy resin. Some examples of that include:

- Industrial epoxy flooring: for factories with very high mechanical and chemical resistance;

- Conductive antistatic epoxy flooring: to conduct static electricity;

- Antibacterial epoxy flooring: for hospitals and centers sensitive to pollution;

- 3D epoxy flooring: one of the novel notions utilized in home flooring and decorative works and has a satisfactory income.

4)Stone Epoxy Resin

Stone Epoxy Resin

Epoxy stone is mostly used in stone cutting firms for the following works:

- Basic processing of stone;

- Fantastic improvement to the back and top of stone slabs (large sheets of stone);

- the process of cutting Stone (cut parts in the mine);

- Application in all stages, before cutting the cube to the end of the sizing stage;

Extraordinary shine and shine after sanding.

3 thoughts on “Applications of Epoxy Resin”